Ever finer, smoother, and more precise, even more sensitive, as error-free as possible and without

rejects: The precision industry is growing – and with it the number of products. If you look closely, you can

recognize Pureon’s signature.

What are we talking about when a manufacturer

requests a surface with exact roughness for his

component? In the technical drawing, the specification is

given in μm (micron). One μm? That is, 0.001 millimeter.

Just for comparison: A human hair measures about 0.05

millimeters, the sticky fiber of a spider 0.006

millimeters. These are the dimensions in which Pureon’s

engineers move with confidence. And what is their task?

The market for technical components made of steel, metal or ceramics is large, the precision industry

has a future, a research-intensive guild. This is because there are countless applications with increasingly

specific requirements, especially in medical, measurement and control technology. Or in automotive

engineering, for example, when sensors need to measure brake pressures or fuel flow.

Water pumps for the dishwasher at home need polished sliding seals, chemical pumps on an industrial scale cannot exist without smooth ceramic rings, and plastic elements come from injection molds, which of course in turn must have excellent surfaces. One must always fit into the other – ultra-precisely and reproducibly. Each part is not installed until the surfaces are perfectly milled, ground, lapped and polished. “Many can do the milling and grinding, but that’s not what we do,” explains Martin Spring, Co-CEO of Pureon. “We take care of the lapping and polishing, and that is a real art!” There are few, but crucial, things that someone who wants to master this art must bring to the table.

Let us go back to the starting point on the way to the optimum solution: Once all the specifications are on the table – the type of workpiece, the desired roughness, the machine configuration at the customer’s plant, the cleaning line and, above all, the desire to reduce the reject rate – then the analysis begins. Either on site at the customer’s or in Lengwil, Switzerland, with the possibilities of test series also in large format. The search is on for exactly the right diamond formulation for the problem in question. Once a solution has been found, the question of rejects is also solved. Pureon manages to reduce the rate significantly.

“Our formulations are tailor-made. Above all, we bring one thing to the table: the ability to understand the big picture,” explains the Co-CEO. Polishing is a matter of know-how from trained specialists with a professional background as engineers, toolmakers, machining specialists or polymechanics. There is no standstill, at Pureon there are regular trainings and education. Knowledge “state-of-the-art”, a lot of experience, reliability and 100 percent quality control of the products counts also in another sub-segment of the precision industry that Pureon serves.

Water pumps for the dishwasher at home need polished sliding seals, chemical pumps on an industrial scale cannot exist without smooth ceramic rings, and plastic elements come from injection molds, which of course in turn must have excellent surfaces. One must always fit into the other – ultra-precisely and reproducibly. Each part is not installed until the surfaces are perfectly milled, ground, lapped and polished. “Many can do the milling and grinding, but that’s not what we do,” explains Martin Spring, Co-CEO of Pureon. “We take care of the lapping and polishing, and that is a real art!” There are few, but crucial, things that someone who wants to master this art must bring to the table.

Let us go back to the starting point on the way to the optimum solution: Once all the specifications are on the table – the type of workpiece, the desired roughness, the machine configuration at the customer’s plant, the cleaning line and, above all, the desire to reduce the reject rate – then the analysis begins. Either on site at the customer’s or in Lengwil, Switzerland, with the possibilities of test series also in large format. The search is on for exactly the right diamond formulation for the problem in question. Once a solution has been found, the question of rejects is also solved. Pureon manages to reduce the rate significantly.

“Our formulations are tailor-made. Above all, we bring one thing to the table: the ability to understand the big picture,” explains the Co-CEO. Polishing is a matter of know-how from trained specialists with a professional background as engineers, toolmakers, machining specialists or polymechanics. There is no standstill, at Pureon there are regular trainings and education. Knowledge “state-of-the-art”, a lot of experience, reliability and 100 percent quality control of the products counts also in another sub-segment of the precision industry that Pureon serves.

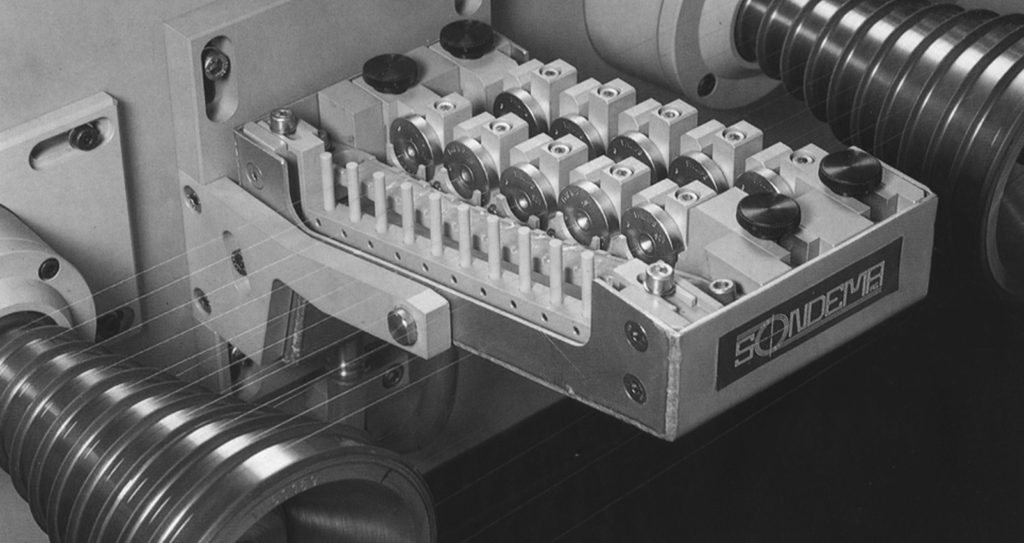

It is about wire drawing dies with different diamond types. With digitalization, the production of

high-quality wires is becoming more and more important: Modern drawing dies are precision tools for

perfectly drawn metals, which are used in every data transmission, in the construction of robots, in

energy supply as well as in modern medicine. Precisely formed material is also needed for electric motors

and current transmission in general, as well as for welding wires, metal fibers, steel wool or heating

elements. It all depends on the geometry of the wire drawing die – and on the surface of the wire. Pureon

delivers precision work for high-tech applications.

Interested in solutions

for the precision industry?

We are happy to share our knowledge with you

and remain at your disposal for any further questions.

and remain at your disposal for any further questions.

Dipl.-Ing. Helge Willer

- Industry Expert

- +41 71 686 60 61

- hwillers@pureon.com