Lapping and polishing slurries

Consistent high performance at minimal process cost

A wide range of slurries tailored to the requirements of specific applications: Ready-to-use lapping and polishing slurries from Pureon combine high-quality components with chemical formulations and micron diamond sizes graded to the highest level of precision – engineered to offer an excellent material removal rate and surface quality. Every time.

Diamond suspensions

Universal-use suspension

Pureon ready-to-use diamond suspensions help you achieve consistently high performance while minimizing total process cost. Our constant innovation on carrier liquid formulations means you get the latest technology to exploit the full power of Pureon‘s precision diamond.SPLENDIS

Universal-use

Water-based suspensions

Water-based suspensions are formulated with a water-soluble carrier liquid. Performance-enhancing additives allow customizing the formulation for specific applications. Water-based suspensions feature good cleaning characteristics and are environmentally friendly. Water-based suspensions are widely used for lapping and polishing of metallic and ceramic parts on all types of lapping plates and pads. Other applications include deburring with brushes and multiwire sawing processes.Oil-based suspension

These suspensions are made with oil-based carrier liquids. They contain additives to increase performance and control application-specific properties such as stability and viscosity. Oil-based suspensions feature excellent lubrication and wetting properties, leading to highest material removal rates and defect-free surface quality. Common applications for oil-based suspensions are lapping and polishing of sapphire and ceramics, orthopedic joints/implants and superfinishing of other hard materials.Glycol-based suspensions

PURE-DS-RT

Glycol-based

Interested in our

Diamond Suspensions?

We are happy to share our knowledge with you

and remain at your disposal for any further questions.

and remain at your disposal for any further questions.

Ueli Siller

-

Product Manager

Diamond Suspension - +41 71 686 60 60

- usiller@pureon.com

Aluminum oxide slurries

ULTRA-SOL®

Acidic colloidal alumina slurries

ULTRA-SOL®

Patterned media slurries

ULTRA-SOL®

Milled alkaline alumina slurry

ULTRA-SOL® AlumaGem

Poly and mono diamond slurry

Interested in our

Aluminum Oxide Slurries?

We are happy to share our knowledge with you

and remain at your disposal for any further questions.

and remain at your disposal for any further questions.

Adam Nielsen

-

Product Manager

Aluminum Oxide Slurries - +1 480 505 3425

- anielsen@pureon.com

Cerium oxide slurries

ULTRA-SOL®

Cerium oxide family

ULTRA-SOL® OPTIQ PRO

Cerium oxide slurry

ULTRA-SOL® C100

Cerium oxide slurry

Interested in our

Cerium Oxide Slurries?

We are happy to share our knowledge with you

and remain at your disposal for any further questions.

and remain at your disposal for any further questions.

Adam Nielsen

-

Product Manager

Cerium Oxide Slurries - +1 480 505 3425

- anielsen@pureon.com

Colloidal silica slurries

ULTRA-SOL®

Standard Colloidal Silicas

ULTRA-SOL®

Non-Drying Colloidal Silicas

NALCO™

Colloidal silica slurries

Interested in our

Colloidal Silica Slurries?

We are happy to share our knowledge with you

and remain at your disposal for any further questions.

and remain at your disposal for any further questions.

Adam Nielsen

-

Product Manager

Colloidal Silica Slurries - +1 480 505 3425

- anielsen@pureon.com

Zirconium oxide slurries

ULTRA-SOL® 100Z

Zirconium oxide slurry

Choosing the right slurry type

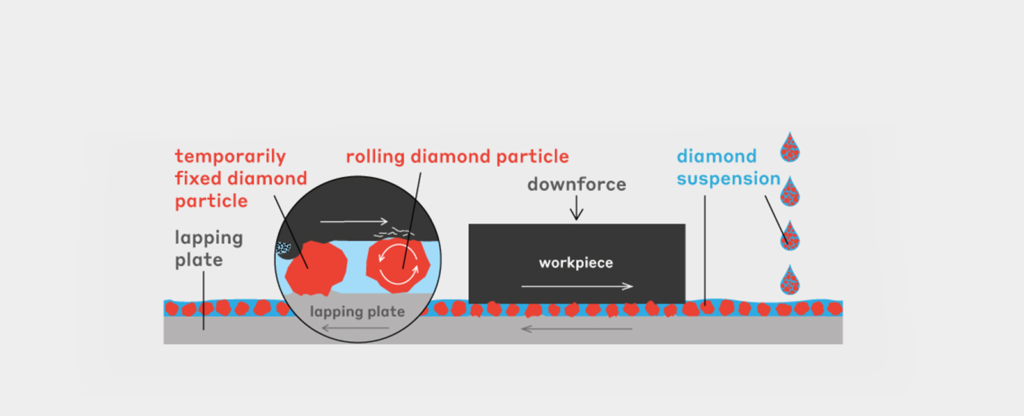

The choice of slurry type depends on several key factors. Oil-based slurries are best suited for processes with highest priority on achieving maximum material removal rate. Oil-based slurries are best used on metallic lapping plates. Water-based slurries are used in lapping and polishing processes on metallic plates or polishing pads. They allow for easy workpiece cleaning and are an environmentally friendly choice.The most obvious differences between lapping and polishing are the amount of material removed and the final appearance of the workpiece. Lapping removes a lot more stock and results in a dull, matte finish, whereas during polishing only a small amount of stock is removed and the polished surface has a reflective finish.

Below an illustration of how lapping works: