Choosing the Right Polish for Precision Optics

- Blog

- Insights

-

Oct 16

- Share post

Choosing the Right Polish for Precision Optics: A Comprehensive Guide from Pureon

At the APOMA Tech Workshop 2024, Caroline Watt, R&D Engineer at Pureon, presented an insightful session on the topic of “Choosing the Right Polish” for precision optics. The session revolved around the complex challenges of polishing high-tech materials and how selecting the right polishing solutions can optimize both surface quality and efficiency in optical manufacturing.

Understanding Pureon’s Commitment to Excellence

Pureon, a globally recognized surface finishing solutions provider, is committed to offering vertically integrated products designed for the most demanding applications. With a strong global presence, Pureon serves customers in over 40 countries, providing tailored solutions for industries working with materials like silicon, sapphire, ceramics, SiC, optical materials, and more. Their solutions cover the entire value chain—from in-house product development to research and application testing—ensuring the highest performance standards for their customers.

Caroline Watt began the presentation by discussing Pureon’s core values of innovation and precision in surface finishing, highlighting their commitment to helping customers overcome challenges in various industries, particularly the precision optics sector.

Key Factors in Choosing the Right Polish

Choosing the right polish for optical surfaces is a multi-faceted process that depends on several factors:

- Material type: Different materials like fused silica and BK7 glass require distinct polishing approaches.

- Surface quality vs. removal rate: Depending on whether the focus is on achieving superior surface quality or maximizing material removal rate (MRR), the choice of polishing consumables and tools will vary.

- Process complexity: From grinding to final polishing, determining the number of process steps required and available polishing tools is crucial to optimizing results.

- Time constraints: The total time allocated to each polishing step, along with how many consumables are used, can impact overall efficiency.

Pureon’s Innovative Polishing Solutions

A significant portion of the presentation focused on three of Pureon’s products: Ultra-Sol OPTIQ PRO, Ultra-Sol C100, SUBA X perforated and OPTIVISION:

- Ultra-Sol OPTIQ PRO is a next-generation precision optics polishing slurry. This product improves upon its predecessor, offering enhanced suspension characteristics, easier dispersion and cleaning, while maintaining superior polishing capabilities.

- Ultra-Sol C100 is an advanced cerium oxide slurry developed for extreme low surface roughness. With its nanoceria formulation and narrow particle size distribution, it allows for superpolishing and meets sub-angstrom surface requirements, a crucial need in optics manufacturing.

- OPTIVISION is a premium polishing pad designed to complement these slurries, delivering precise results across multiple stages of the polishing process. The combination of Ultra-Sol slurries with OPTIVISION pads enables highly efficient polishing with exceptional surface smoothness.

- SUBA X perforated is an intermediate polishing pad designed to provide excellent planarization and defect-free surface quality. It is widely used in optical polishing processes for its ability to offer a balanced combination of material removal and surface smoothness, making it an ideal choice for intermediate polishing steps before moving to finer finishing stages.

Case Study: Fused Silica and BK7 Polishing

Caroline presented a detailed case study showcasing how Pureon’s products outperform other polishing solutions in real-world scenarios. The study involved two types of glass—fused silica and BK7—and a multi-step polishing process using Ultra-Sol OPTIQ PRO, OPTIVISION, SUBA X perforated, and Ultra-Sol C100.

The key findings from the study include:

- In the intermediate polishing step, Ultra-Sol OPTIQ PRO combined with SUBA X perforated significantly reduced surface roughness in a short amount of time.

- The final polish steps, which included OPTIVISION and Ultra-Sol C100, achieved remarkable surface quality improvements, with surface roughness reaching below 1 nanometer.

- OPTIVISION pads provided the necessary precision and consistency, particularly in the final polishing steps, ensuring that the polishing slurries were used to their maximum potential.

This case study demonstrated that the combination of Ultra-Sol OPTIQ PRO, SUBA X perforated, Ultra-Sol C100, and OPTIVISION pads is a winning formula for achieving superior optical surface finishes.

Experimental Results: Measurable Improvements

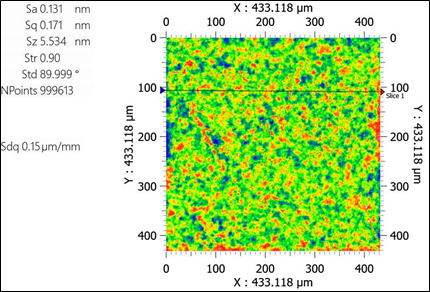

The presentation also featured extensive experimental data, showcasing the effectiveness of Pureon’s products. The experiments were conducted under controlled conditions, with polishing performed using a Lapmaster 12 single-side tool. Key performance metrics such as MRR (Material Removal Rate) and surface roughness (Sa) were measured using ZeGage Pro HR, a coherence scanning interferometer.

Results showed:

- For Fused Silica, final polishing with Ultra-Sol OPTIQ PRO and OPTIVISION reduced surface roughness by up to 65%.

- When using Ultra-Sol C100 in the final polish step with OPTIVISION, surface roughness on fused silica samples reached as low as 0.131 nm, confirming the slurry’s ability to meet the highest precision standards in optics.

These measurable improvements highlight Pureon’s role as an innovative driver in the optics polishing industry, offering products that ensure not only speed but also unparalleled quality.

A Future-Oriented Approach to Surface Finishing

Pureon’s vision is to remain the global go-to provider for surface finishing solutions in high-tech materials. Caroline concluded the session by emphasizing the importance of innovation in the development of polishing slurries and pads. As new challenges arise in optics manufacturing, such as tighter tolerances and more complex geometries, Pureon continues to push the boundaries of what’s possible with their products.

Do you want to see the full presentation? Contact us for more details. Sales Contacts