Pureon Launches New SiC Polishing Solutions: IRINO-PROSiC Polishing Pad and PURE-DS-RT Suspension

- Blog

- Insights

-

Oct 03

- Share post

Pureon Launches New SiC Polishing Solutions: IRINO-PROSiC Polishing Pad and PURE-DS-RT Suspension

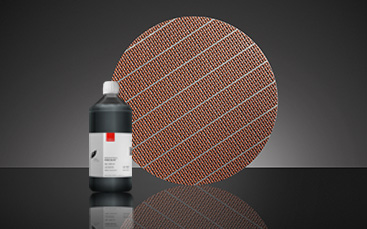

We think solutions through to the end with the new IRINO-PROSiC composite polishing pad and the associated suspension PURE-DS-RT. Both consumables are specifically designed to improve your polishing process of Silicon Carbide (SiC) wafers. They deliver an effective approach to Direct Mechanical Planarization (DMP) and Rapid Thinning processes.

IRINO-PROSiC: The Next Evolution in SiC Polishing

The IRINO-PROSiC composite polishing pad is the newest addition to our renowned IRINO family, developed with advanced SiC DMP processes in mind. This polishing pad is engineered to provide superior surface finishes down to 3 nm Ra and ensures an exceptional stock removal rate, positioning it as a highly competitive alternative to traditional SiC grinding methods.

Key features include:

- Innovative design for Pureon’s Rapid Thinning process – ideal for transitioning directly to CMP.

- Best-in-class performance for SiC polishing – offering excellent geometry and flatness without edge round-off.

- Flexible and dressable system – suitable for single-side and double-side machines.

- Self-adhesive backing – enabling easy application to any existing metal carrier plate.

With IRINO-PROSiC, users can expect consistent results and a competitive edge in SiC polishing, whether targeting high surface quality or significant material removal.

PURE-DS-RT: The Perfect Suspension Partner

To maximize the capabilities of IRINO-PROSiC, we introduce the PURE-DS-RT suspension, specially formulated for Pureon’s Rapid Thinning process. This water-soluble suspension is designed to prevent drying when exposed to air, making it both user-friendly and environmentally conscious.

Key features include:

- Perfect compatibility with IRINO-PROSiC – ensuring optimal results in Rapid Thinning applications.

- High lapping pressures for increased removal rates.

- Stable, user-friendly formulation – easy to clean and environmentally friendly.

- Tailored for versatility – available in six formulations to meet the specific needs of various applications, including SiC wafers and hard materials like sapphire.

When paired together, IRINO-PROSiC and PURE-DS-RT form a dynamic duo for SiC wafer processing. This innovative combination allows manufacturers to achieve improved surface quality and efficiency, making it easier to transition from SiC DMP directly to CMP.

Whether you are seeking enhanced surface quality, better flatness, or higher material removal rates, Pureon’s new products are tailored to meet the challenges of modern SiC polishing and Rapid Thinning processes. Discover how the IRINO-PROSiC polishing pad and PURE-DS-RT suspension can elevate your SiC polishing performance.

For more details please contact us.