MH polishing pads are uniquely designed for polishing and inishing a wide variety of surfaces where latness and ultra-precision surface

inish is critical. These materials include glass surfaces, ceramic components, precision lenses, optics, and aluminum disks. An advanced

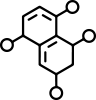

polyurethane formula is the base of all MH polishing pads. This formula produces a microcellular pore matrix throughout the material

and yields an extremely tough, durable surface to withstand the demands of inishing and polishing with abrasives. The MH structure

provides maximum use of the abrasive by embedding it into the top surface of the pad to allow greater cutting action and minimizing

free particles that can contribute to scratching.

Highlights

Open pore structure

Available in different thicknesses

Available in multiple surface textures such as plain and XY grooved

Product Specifications

Base material

Urethane

Shelf life

12 months

| Slurry additive | Base material | Compressibility [%] | Hardness | Hardness Test | Thickness [mils] |

|---|---|---|---|---|---|

| MHS15S | Urethane | 3.05 | 84 | JIS | 0.5 |

Interested in the

MHS15S Polishing Pad?

We are happy to share our knowledge with you

and remain at your disposal for any further questions.

and remain at your disposal for any further questions.

Adam Nielsen

- Product Manager

- anielsen@pureon.com