Introducing Pureon’s new IRINO Product Family: Application-oriented for a wide variety of materials

- Blog

- Insights

-

Apr 29

- Share post

Introducing Pureon’s new IRINO Product Family: Application-oriented for a wide variety of materials

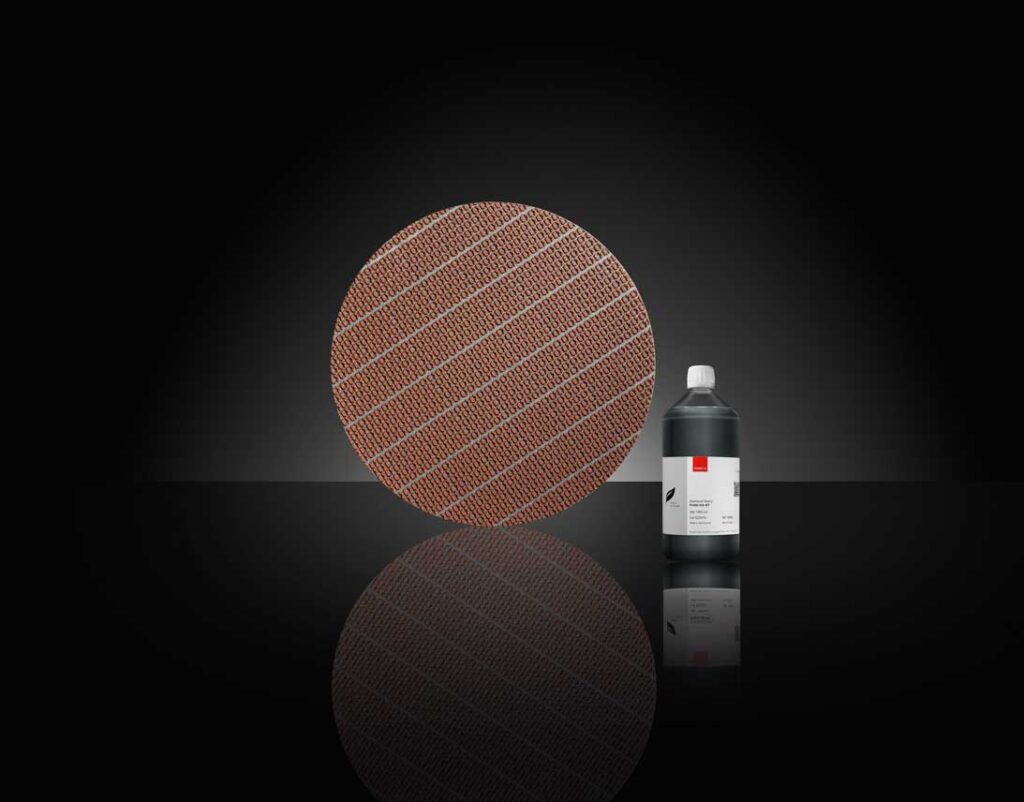

At the heart of precision manufacturing is the need for optimum surface finish across a range of materials, from the hardest ceramics to various metals. To meet these ever-increasing demands, Pureon has launched the IRINO family of composite pads— three pads, each customized to the requirements of the specific application. Our developments are always based on the Total Process Solutions approach, which is why the entire IRINO family combined with the PURE-DS-RT suspension is the ideal choice for thinning of hardest materials.

A Leap Forward in Application-oriented Polishing

The IRINO product family is a result of extensive research and development in the field of advanced materials science and a further development of the well-established IRINO-PRO-C composite polishing pad. These pads leverage proven composite technology to optimize performance for workpieces made of challenging materials such as silicon carbide (SiC), sapphire, ceramics, metals, and plastics.

Polishing is more than just achieving a shiny surface; it’s about removing material in a controlled, predictable manner while preserving the structural integrity of the workpiece. Traditional polyurethane (PU) pads have long been used for polishing, but they fall short in terms of suspension efficiency and durability. The IRINO family addresses these limitations through its specialized bond systems and unique designs, which not only extend the pad’s lifespan but also reduce diamond suspension consumption—critical factors for lowering operational costs and improving sustainability.

The IRINO Family Breakdown

IRINO-PROSiC: The Future of Silicon Carbide wafer processing

IRINO-PROSiC is designed to tackle the complex requirements of silicon carbide (SiC) wafering, particularly in applications where Rapid Thinning is essential. SiC, widely used in the semiconductor and LED industries, is notoriously hard to polish due to its extreme hardness. The honeycomb structure of the IRINO-PROSiC pad is optimized for SiC polishing, offering superior material removal rates while maintaining excellent surface quality.

Key to its design is a 1 mm resin bond height, which provides enhanced durability, allowing the pad to last longer during intensive SiC polishing processes. This is particularly beneficial in high-throughput manufacturing environments, where minimizing downtime is critical.

IRINO-PRO: For Hard Materials

IRINO-PRO offers a versatile solution for polishing hard materials like sapphire, ceramics, and hard metals. Its resin bond height of 0.8 mm is optimized for these materials, and it comes in two bond versions:

- IRINO-PRO-M: A medium-hard bond system ideal for achieving balanced material removal and surface finish.

- IRINO-PRO-H: A hard bond system suited for more aggressive polishing processes, where faster material removal is a priority.

The flexibility of the IRINO-PRO pad makes it suitable for a wide range of industries, from precision optics to aerospace, where the highest quality surface finishes are required on hard materials.

IRINO-PLUS: Perfect for Metallographic Polishing

Metallographic polishing requires exceptional control to reveal microstructural details without damaging the sample. IRINO-PLUS, with its 0.6 mm resin bond height, is designed specifically for metallographic applications, offering both medium-hard (IRINO-PLUS-M) and hard (IRINO-PLUS-H) bond systems. This makes the pad ideal for preparing metal samples for microstructural analysis, ensuring that researchers and quality control professionals can achieve consistent, reliable results.

Why We Innovate: Efficiency, Durability, and Precision

The IRINO family was developed as a direct response to the growing need for more efficient and sustainable polishing solutions. As industries continue to push the boundaries of what materials can do—especially in fields like semiconductors, where silicon carbide is revolutionizing electronics—polishing processes must also evolve.

Traditional polishing pads are often inefficient in their use of diamond suspensions, requiring high volumes of suspension to achieve the desired finish. The IRINO family’s superior suspension retention capabilities mean less diamond suspension is needed, which directly translates to cost savings and a smaller environmental footprint. Furthermore, the extended pad life ensures fewer replacements, reducing both operational costs and downtime.

The Science behind the Efficiency

At the core of IRINO’s performance is its composite structure, designed to work in an optimal synergy with Pureon’s advanced diamond suspensions. With our PURE-DS-RT suspension series, we developed the perfect addition to these three pads. There are six specific formulations tailored for different applications, depending on the workpiece. The pads’ unique bond systems allow for optimal suspension interaction, maximizing the use of the diamond particles while minimizing waste. Compared to conventional PU pads, IRINO achieves more efficient material removal and requires less frequent replenishment of suspension.

Additionally, the half-circle bonding design of IRINO-PRO and IRINO-PLUS has been developed to provide more even distribution of polishing forces across the surface of the workpiece, ensuring consistent polishing performance and reducing the risk of localized over-polishing, which can damage the part.

The IRINO family’s introduction marks another step forward in Pureon’s commitment to innovation, precision, and progress. As the world of materials science continues to evolve, so too will the tools and

technologies we develop to shape it. The IRINO family is a shining example of this progress, designed to meet the needs of today while anticipating the challenges of tomorrow.

Ask our Sales representatives about what we can do for you now.